2015 RANSOHOFF SURE CLEAN SC-30

2015 RANSOHOFF SURE CLEAN SC-30

Contact us for price

Kentucky

Description

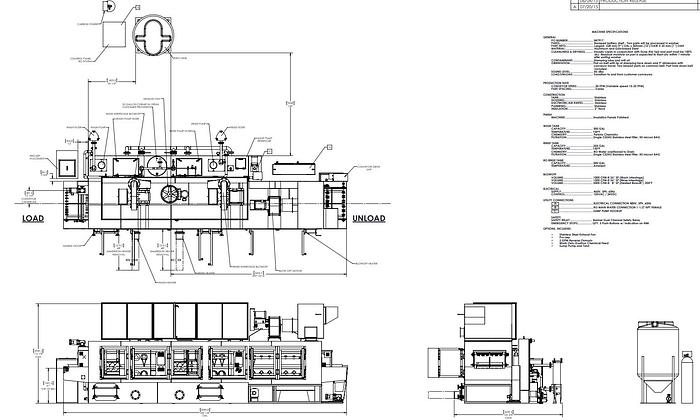

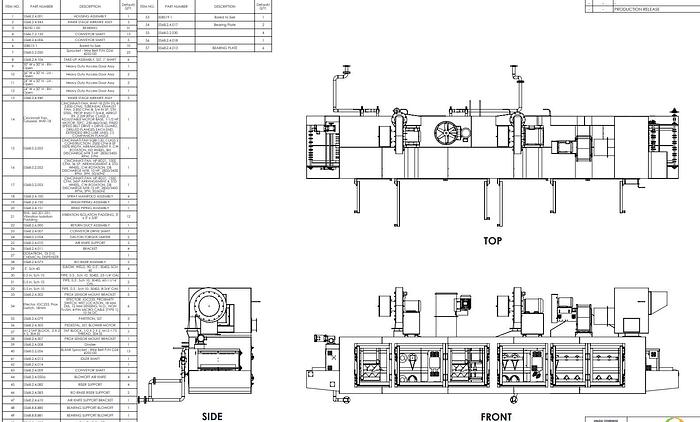

RANSOHOFF SURECLEAN SC-30

YEAR 2015

STOCK #104071

BASIC INFORMATION

===========================================================

ANSOHOFF SURECLEAN SC-30, YEAR 2015, LOCATION TN, BUYER TO LOAD & SHIP.

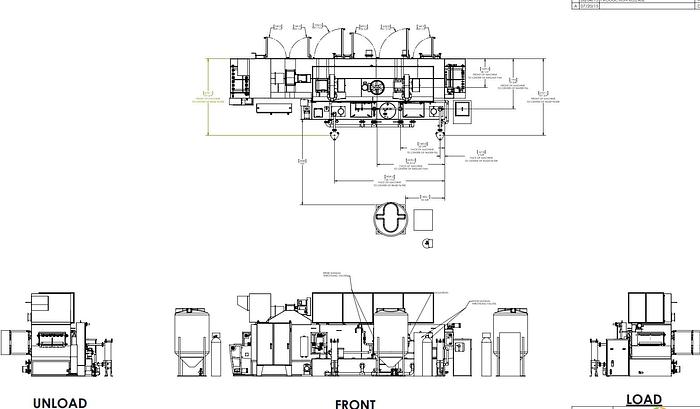

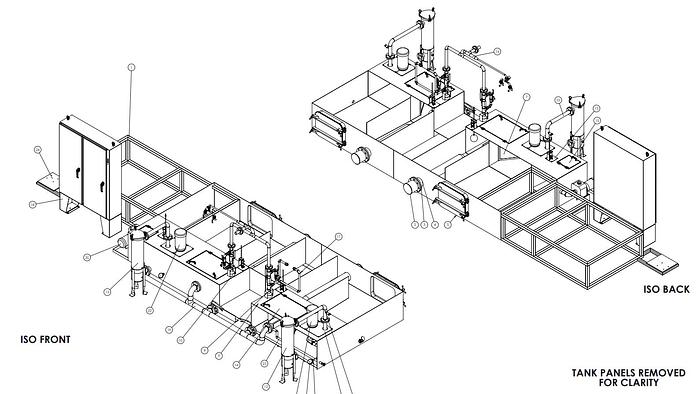

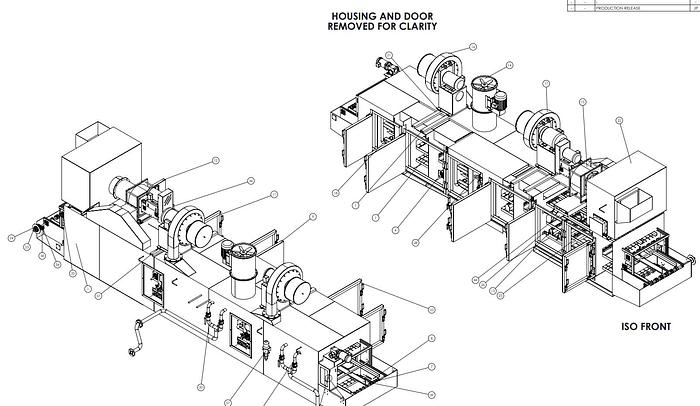

This machine is a multi-stage parts cleaning machine. All stages are insulated and compartmentalized with individually adjustable exhaust dampers, reducing system heat loss. Parts are placed on a flat wire belt or custom fixture and travel the full length of the machine. While moving through the tunnel there are one or more stages that the parts go through to complete a cleaning cycle. These stages remove cutting oils, debris, dirt and other contaminants that may be left over from the manufacturing operation. • WASH STATION: Through the use of pressurized jets and specialized cleaning chemicals, the parts are cleaned. This removes cutting oils, debris, dirt and other contaminants that may be left over from the manufacturing operation.

• INTER-STAGE BLOW-OFF STATION: Ambient air is forced through Blow-off Knives which removes the liquid left on the part during the cleaning process.

• RINSE STATION: Through the use of pressurized jets and clean heated water, parts are rinsed to remove any of the chemical and remaining debris from the part.

• INTER-STAGE BLOW-OFF STATION: Ambient air is forced through Blow-off Knives which removes the liquid left on the part during the cleaning process.

• RUST INHIBITOR STATION: Through the use of pressurized jets and specialized chemistry, parts are sprayed to inhibit rust.

• INTER-STAGE BLOW-OFF STATION: Ambient air is forced through Blow-off Knives which removes the liquid left on the part during the cleaning process.

• BLOW-OFF STATION: The final stage is the blow-off cycle. Air is heated and is forced through Blow-off Knives which removes the liquid left on the part during the cleaning process. The air can be compressed and/or heated. A manual ball valve will spray the blow-off station with fresh water to remove debris build up. This may be completed weekly

Additional options for the machine include the following:

• Pro-Sep Oil Control System: A closed loop oil control system permits continuous overflow of all floating oil and similar contaminates from the main wash tank. Oil and solution are elevated to a vertical separation tank permitting the oil to rise while the solution is forced to the bottom port for return to the main wash tank. Oil is collected in a chamber that removes final traces of solution before discharge to the waste container.

• Ultrasonics: The ultrasonics cleaning technology uses multiple frequency ultrasonic generators and waveform ultrasonic generators. This is designed to remove sub-micron particles. This energy speeds up and enhances the cleaning effect of the chemistries.

• Line Rinse: Use of an additional line rinse is a solenoid controlled line rinse using fresh solution after the rinse cycle prior to the blow-off cycle. The waste from this system can be directed to one of two locations:

o Direct to the rinse or wash tank which allows for periodic tank skimming.

o Direct to the rinse holding tank and/or to the drain

231-526-9525

Specifications

| Manufacturer | RANSOHOFF |

| Model | SURE CLEAN SC-30 |

| Year | 2015 |

| Condition | Used |

| Stock Number | 104071 |