ROLLOMATIC 6000XL 9 AXIS TOOL & CUTTER CUTTER GRINDER

No longer available

ROLLOMATIC 6000XL 9 AXIS TOOL & CUTTER CUTTER GRINDER

Harbor Springs, MI

Description

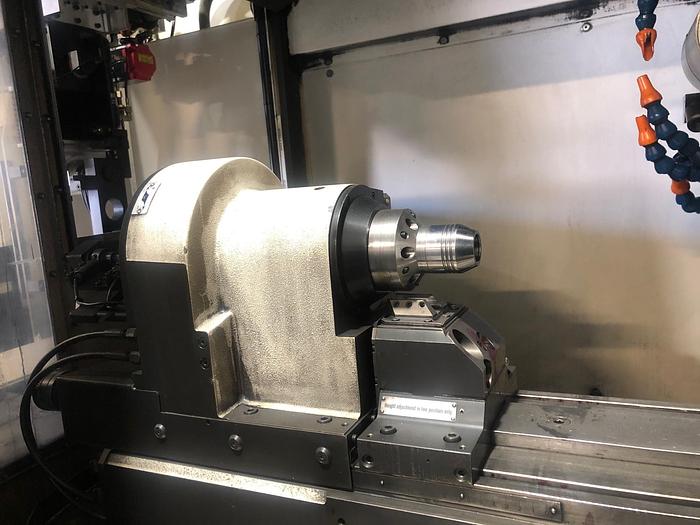

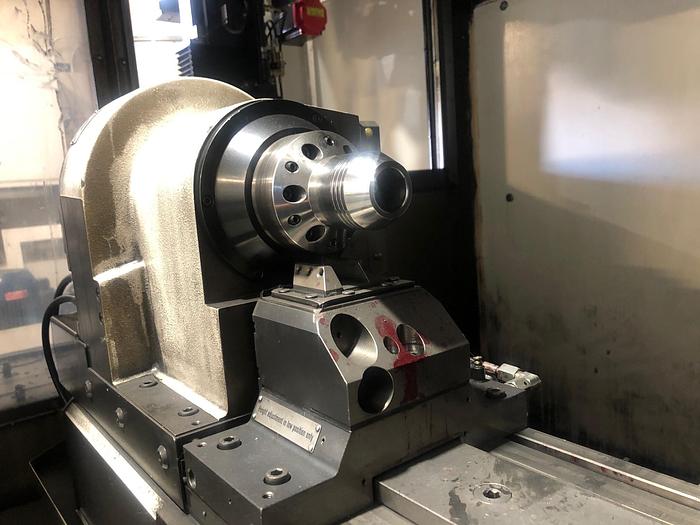

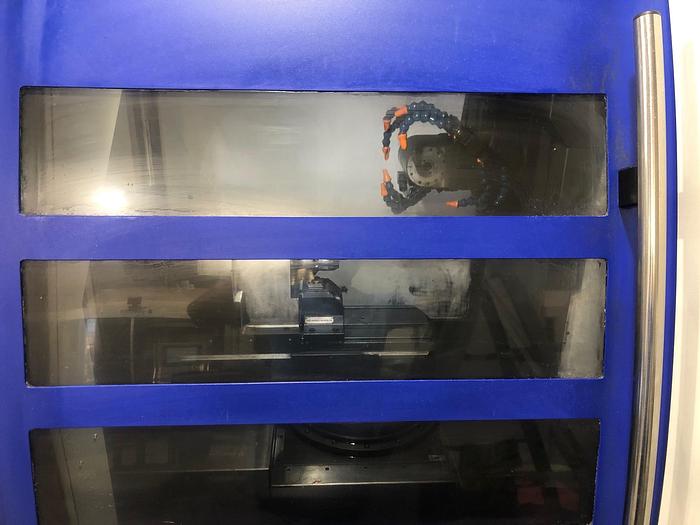

ROLLOMATIC 6000XL 9 AXIS CNC GRINDER STOCK#103911 Super Precision Tool Grinding Center with 9-axis CNC control FANUC 160-iMB (6 machine axes and 3 loader axes) For the production grinding of rotary cutting tools such as endmills, drills, step tools, reamers, burs, routers, medical tools as well as special applications in carbide, HSS and similar materials. Specifcations: ================================================== Part No. Qty Description 6000 1 Basic machine including standard equipment Technical Data: X-axis Linear hydrostatic, longitudinal axis Stroke 280 mm ( 11") Resolution 0.0001 mm (.000004") Fast travel 20 m/min. (787"/min.) Linear glass scale 0.0001 mm Y-axis Linear hydrostatic, vertical axis Stroke 245 mm (9.5") Resolution 0.0001 mm (.000004") Fast travel 15 m/min. (590"/min.) Linear glass scale 0.0001 mm Z-axis Linear hydrostatic, cross axis Stroke 355 mm (14") Resolution 0.0001 mm (.000004") Fast travel 20 m/min. (787"/min.) Linear glass scale 0.0001 mm A-axis rotary hydrostatic, grinding head rotation Stroke 240° Resolution 0.0001° Fast travel 60 rpm (1 sec. for 180°) Rotary glass scale 0.0001° B-axis rotary hydrostatic, workhead rotation Stroke neg. 45° to pos. 135° (180°) Resolution 0.0001° direct drive Fast travel 60 rpm Rotary glass scale 0.0001° C-axis rotary hydrostatic, tool rotation Stroke endless Resolution 0.0001° Fast travel 550 rpm Encoder rotary encoder on AC motor, 0.0001° Workhead: - Hydrostatic tool rotation - Collet system W31.75 - Clamping capacity 32 mm (1.1/4") - Grinding range 3 - 32 mm 1/8" - 1.1/4" - Cylindrical grinding capability 550 rpm - Hydraulic clamping with hydraulic ejector rod - Super precision V-block shank guide hydraulic, with V or half-moon guides - Super precision steady rest hydraulic, with V or half-moon rests (mounted on air pads for ease of adjustment) Grinding Head: - Hydrostatic grinding spindle - Grinding motor 20 kW 28 HP with internal cooling - Spindle speed up to 8,000 RPM - Double-ended spindle - Max. dia. of wheels dia. 200 mm (8") - Max. number of wheels (total) up to 8 - Graphic display of load meter with 2 alarm levels. Automatic Loader: - Shank dia. 1 - 12.7 mm .04" - .5" - Max. overall length 300 mm(12") - Speed: 65 m/min. (2,560"/min.) - Clamping hydraulic - Including automatic pallet changer with up to 4 cassettes Control System: - Machine control FANUC 160-iMB 9-axis Interface FANUC/PC including Windows 2000 Rollomatic Software: Grinding: Endmills, ballnose and radius endmills Taper tools, ballnose and radius taper endmills Drills/step drills, step tools Burs (industrial, aluminum-cut, surgical, dental) Routers Medical/surgical components Simulation: VirtualGrind PC programming system/simulation FluteCalc 2-D simulation of flute shapes 3DCalc 3-D simulation of any tools BurCalc 2-D and 3-D simulation of burs TaperCalc 2-D and 3D simulation of tapered tools ISO programming using Rollomatic co-ordinate system, incl. 3-D simulation Probing routines (flutes and coolant holes) Teach-in (wheel shapes and machine calibrations) Graphic wheel display with zero offsets Various control diagnostics Other Data: Electrical equipment 3 x440/480V 60Hz, (alternate voltage at extra cost) Paint finish Blue RAL5002 White RAL9010 Weight 20,000 lbs Power consumption 55 kW Coolant Equipment for In-Coming Oil: - Flow meter to monitor the coolant flow - Pressure meter to monitor the coolant pressure Coolant Equipment for Out-Going Oil: - Integrated coolant tank for discharge of coolant with level control and discharge pump 200 liter/min. (55 gal/min.) Hydrostatic System: Oil chiller to regulate and control the temperature of the hydrostatic oil List of tooling included: Cost of tooling alone: $95,000 W 31.75 Collet Spindle Adapter 2 Collet 31.75 Extended Nose 3/8" 1 Collet 31.75 Extended Nose 1/2" 2 Collet 31.75 UP 1/2" 1 Collet 31.75 UP 9/16" 1 Collet 31.75 UP 5/8" 2 Collet 31.75 UP 3/4" 1 Collet 31.75 UP 1" 2 Collet 31.75 UP 10mm 2 Collet 31.75 UP 12mm 3 Collet 31.75 UP 14mm 1 Collet 31.75 UP 16mm 2 Collet 31.75 UP18mm 2 Collet 31.75 UP 20mm 1 Collet 31.75 UP 25mm 3 Adapter for Centering V Block 10-20mm 1 Centering V Block MD 20mm Rect for 8-12mm 1 Centering V Block MD 20mm Rect for 12-19.5mm 2 Centering V Block MD 20mm Rect for 18-25.4mm 1 Centering V Block MD 20mm Rect for 25-32mm 1 Pressure Finger for V Centering 10mm left 3 Pressure Finger for V Centering 20mm left 4 Pressure Finger for V Centering 10mm right 3 Pressure Finger for V Centering 20mm left 4 Movable Robot Gripper V 10mm right 1 Movable Robot Gripper V 10mm left 1 Movable Robot Gripper V 20mm right 2 Movable Robot Gripper V 20mm left 2 Fixed Robot Gripper 20mm 3 Steady Rest U MD 25mm rect. D 8mm 2 Steady Rest U MD 25mm rect. D 10mm 2 Steady Rest U MD 25mm rect. D 12mm 2 Steady Rest U MD 25mm rect. D 18mm 1 Steady Rest U MD 25mm rect. D 16mm 2 Steady Rest U MD 25mm rect. D 20mm 2 Steady Rest U MD 25mm rect. D 25mm 1 Steady Rest U MD 25mm rect. D 1" 2 Steady Rest U MD 25mm rect. D 3/8" 1 Steady Rest U MD 25mm rect. D 1/2" 2 Steady Rest U MD 25mm rect. D 5/8" 2 Steady Rest U MD 25mm rect. D 3/4" 2 Intermediate Sleeve for Schunk d. 25.4 Internal d. 8mm 1 Intermediate Sleeve for Schunk d. 25.4 Internal d. 10mm 1 Intermediate Sleeve for Schunk d. 25.4 Internal d. 12mm 1 Intermediate Sleeve for Schunk d. 25.4 Internal d. 16mm 1 Intermediate Sleeve for Schunk d. 25.4 Internal d. 18mm 1 Intermediate Sleeve for Schunk d. 25.4 Internal d. 20mm 1 Intermediate Sleeve for Schunk d. 25.4 Internal d. 3/8" 1 Intermediate Sleeve for Schunk d. 25.4 Internal d. 1/2" 3 Intermediate Sleeve for Schunk d. 25.4 Internal d. 5/8" 1 Intermediate Sleeve for Schunk d. 25.4 Internal d. 3/4" 1 Wrench for Intermediate Sleeve Extraction 1 Wheel Arbor d. 40 x 60mm 14 Wheel Arbor d. 40 x 100mm 7 Wheel Arbor d. 40 x 130mm 6

Specifications

| Manufacturer | ROLLOMATIC |

| Model | 6000XL 9 AXIS TOOL & CUTTER CUTTER GRINDER |

| Condition | Used |

| Stock Number | 103911 |