2020 ABB NEVER USED IRB 6700-235/2.65 6 AXIS ROBOT WITH IRC5 CONTROLLER

2020 ABB NEVER USED IRB 6700-235/2.65 6 AXIS ROBOT WITH IRC5 CONTROLLER

Contact us for price

Location:Imlay City, MI

Description

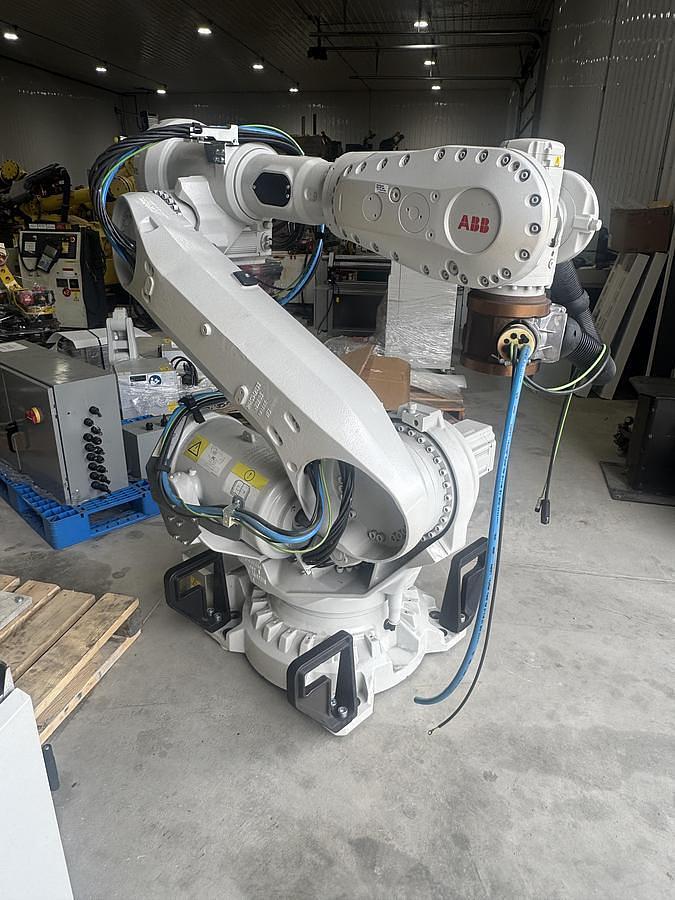

1-ABB IRB 6700-235/2.65 6 AXIS ROBOT PURCHASED FOR TRAINING NEVER USED,

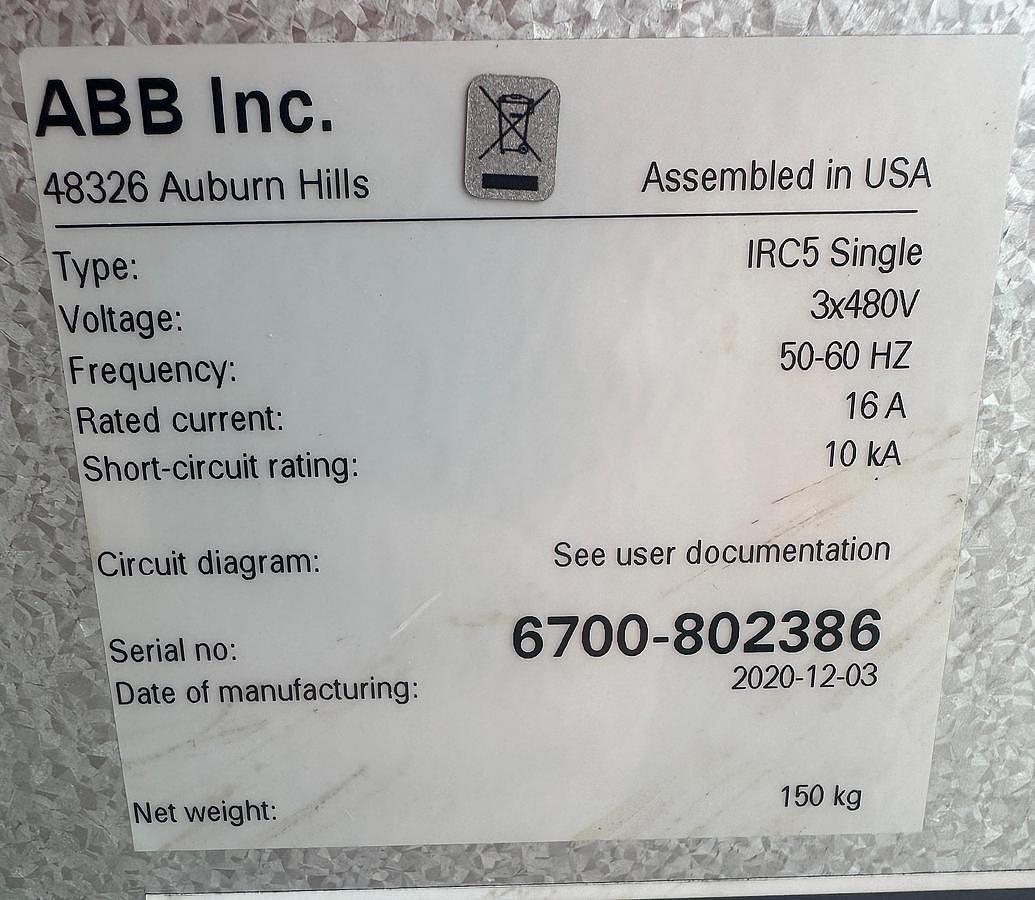

WITH IRC5 CONTROLLER, PENDANT, AND CABLES. SEE VIDEO UNDER POWER.

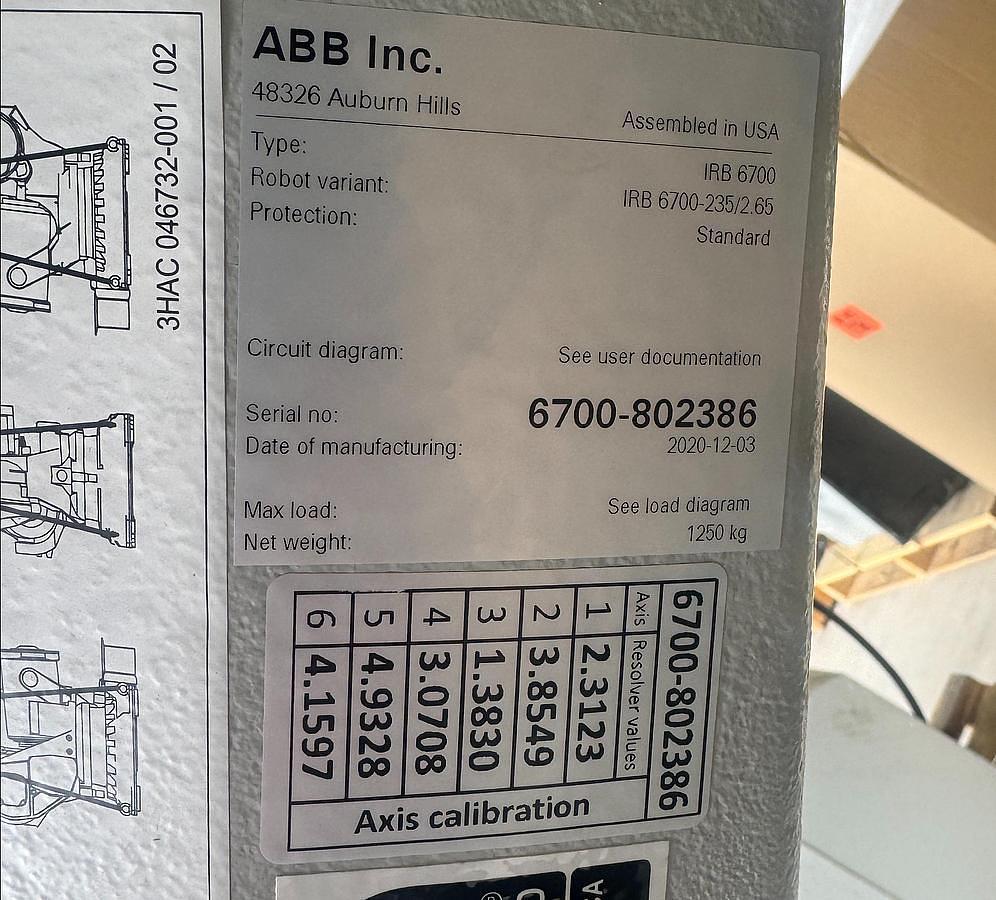

SERIAL NUMBER 6700-802386

DATE OF MFG. 12/2020

STK#104167

==================================

SPECIFICATIONS WHILE OBTAINED FROM SOURCES DEEMED

RELIABLE ARE SUBJECT TO CHANGE WITHOUT NOTICE

AND TO VERIFICATION BY BUYER

THIS IS A BEAUTIFUL ROBOT READY TO BE DEPLOYED INTO YOUR FACILITY

FROM THE OEM:

The 7th generation of large industrial robots. The IRB 6700 family of robots is a natural evolution following 40 years of large robot heritage at ABB. This 7th generation of large ABB robots features a multitude of next generation improvements derived from intimate customer relationships and exhaustive engineering studies.

Key features

The IRB 6700 family is the highest performance robots in the 150-300 kilogram class, now with a 20 percent reduction in total cost of ownership achieved through more robust design, longer service intervals, increased efficiency and simplified maintenance versus the previous generation.

Multiple variants

These robots enhances ABB’s portfolio by combining greater uptime, higher payloads and longer reach for use in Spot Welding, Material Handling and Machine Tending applications at the automotive and the general industries. This array of robot variants has payloads from 150 to 300 kg, reaches 2.6 to 3.2 meters, and are avalible as floor mounted and inverted versions.

Robust and reliable

The entire robot structure has been strengthened with higher rigidity, resulting in increased accuracy, shorter cycle time and better protection. It has been built to withstand the harshest working environments and is available with ABB’s ultimate Foundry Plus 2 protection system. The IRB 6700 has also been validated and tested with more robot prototypes than ever before to ensure that the predictions for reliability were accurate in the real world.

Simplified maintenance

In designing the robot, easier serviceability was identified as a critical aspect for improving its total cost of ownership. Therefor service and repair time has been reduced by 15 percent.

Access to motors has also been improved and technical documentation for maintenance has become easier to read and understand through the use of improved graphics and 3D simulations called “Simstructions.”

Built around LeanID

Every robot in the 6700 family has been designed to accommodate LeanID—a new Integrated Dressing (ID) solution meant to achieve a balance between cost and durability by integrating the most exposed parts of the dress pack into the robot. Equipping an IRB 6700 with LeanID makes it easier to program and simulate with predictable cable movements, creates a more compact footprint, and lengthens service intervals due to lessened wear and tear.

Features and benefits:

Increased service intervals and decreased service times

Longer uptime—mean time between failures 400,000 hours

Available with Lean ID for cost effectively increasing dress pack lifetimes

More robust with a rigid structure and a new generation of motors and compact gearboxes

Increased speed and shorter cycle times—on average 5 percent faster

Improved accuracy and higher payloads

Built to operate in the harshest environments—available with Foundry Plus 2 package

15 percent lower power consumption

The IRB 6700 family includes 10 variants, available as floor mounted and inverted versions.

Robot Specifications:

Axes: 6

Payload: 235kg

H-Reach: 2650mm

Repeatability: position ±0.05mm pathway ±0.10mm

Robot Mass: 1250.00kg

Structure: Articulated

Mounting: Floor

Robot Base: 1004 x 720mm

Robot Motion Speed:

J1 100 °/s (1.74533 rad/s)

J2 90 °/s (1.5708 rad/s)

J3 90 °/s (1.5708 rad/s)

J4 170 °/s (2.96706 rad/s)

J5 120 °/s (2.0944 rad/s)

J6 190 °/s (3.31613 rad/s)

Robot Motion Range:

J1 ±170° option 220°

J2 -65° + 85°

J3 -180°/+70°

J4 Default: ±300°

J5 ±130°

J6 Default: ±360°,3 Max. rev: ±93.7

APPLICATIONS:

MATERIAL HANDLING

SPOT WELDING

DISPENSING

MACHINE TENDING

MATERIAL REMOVAL

EQUIPPED WITH:

ABB IRB 6700-235/2.65 MECHANICAL UNIT

ABB IRC5 CONTROLLER

ABB ROBOT CONNECTION CABLES

ABB COLOR TEACH PENDANT

231-526-9525

Specifications

| Manufacturer | ABB |

| Model | NEVER USED IRB 6700-235/2.65 6 AXIS ROBOT WITH IRC5 CONTROLLER |

| Year | 2020 |

| Condition | Used |

| Stock Number | 104167 |